Metal and steel components are a vital part of numerous industries and deliver strength and stability. The two important processes in different sectors are welding and cutting. The process where two metal or steel parts are joined together is ‘welding.’ On the other hand, cutting involves separating a part of steel or metal from its source.

Both welding and cutting are not easy and require special equipment and careful technique. During the welding process, intensive heat forms a joint or ‘weld’ between two metal pieces. The heat is given by oxygen and oxy-fuel such as acetylene, propane, and natural gas.

Steel and metal parts have the strongest surfaces, and it is not easy to cut through them. There are sturdy metal cutters, but it requires tremendous effort, and these cutters are only suitable to cut in a straight line. The problem or challenge arises when a circular cut is needed on a metal surface or steel pipe.

The cutting of metal parts also requires a tremendous amount of heat to melt away the part you want to cut. The high temperature again involves oxygen and other oxy-fuel. The cutting process may also involve single-point or multi-point tools.

The single-point tool, as the name implies, has a single edge and is suitable for shaping and cutting, while multi-point is ideal for grinding and drilling purposes. The necessary things to consider before choosing a metal cutting tool are

- The strength of the cutter

- The hardness and toughness at high temperature may not deform the material of the cutter

- Resistance to normal wear and tear during the cutting process

There are quite a few methods to cut metal or steel plates, but it depends on the type and thickness. Some methods are economical, while some are expensive.

The Important Use of Circle Shape Cutter

Experts recommend that the material of the cutter should be harder than the material which is going to be cut. The tool must be able to withstand high temperatures due to oxy-acetylene flame. Getting a circular cut is quite tricky and complicated.

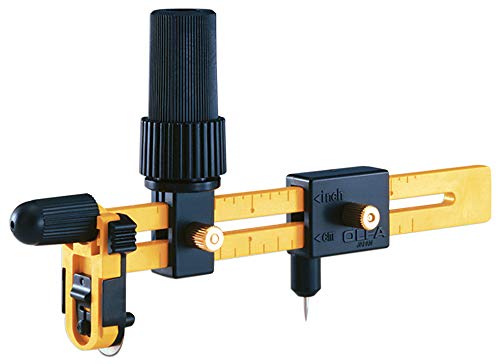

Workers need first to get relevant equipment that can easily cut the metal part in a circular shape. Unfortunately, there are not many tools that can cut in a circle shape. However, the advancement of technology has given way to a circle shape cutter, also known as a ‘circle burner.’ The cutter works along with a torch attachment that provides the flame.

The circle burner is best to make the accurate circular cut at every angle and save a considerable amount of time and effort. A circle burner is an essential tool in fabrication stores, auto repair shops, metal scraping, and industrial construction. The tool is vital to achieving precision and accuracy, which is hard when requiring a circular cut. The circle cutter is best to achieve cuts from 1 inch to 12 inches and 24 inches in diameter.

What is the Common Method of Cutting Metal Parts?

For decades oxy-acetylene welding and cutting were most common due to their cost-effectiveness and efficiency. But in recent times, due to innovation, arc welders are best for cutting metal in any shape. The arc welders are fast and give consistent cuts.

The oxy-acetylene process was introduced way back in 1903. The pairing of oxygen and fuel such as acetylene produces flames that burn at 6,332 ºF.

The melting process involves the use of a torch that cuts or welds the material. Acetylene is popular as it generates high temperatures. However, other oxy-fuel options include propane, natural gas, propylene, and hydrogen. Oxidation is when oxygen combines with the oxy-fuel to generate heat and melt the metal piece.

A plasma torch can cut through a thick wall measuring 3 inches. On the contrary, an oxy-acetylene torch can cut through a material with a thickness of up to 24 inches. A circle cutter can easily attach with an oxy-acetylene or plasma torch. Any radius cuts or holes of any size can be cut without any difficulty. One only needs to place the sharpened point on the center mark and cut the metal piece.

The Need to Ensure Safety Rules

Both welding and cutting involve intensive heat due to the high temperatures of the flames, which calls for proper safety measures. A worker who performs the metal cutting must wear protective gloves, a helmet, and goggles to avoid the heat and sparks.

The steps a worker need to perform to get a circular-cut are

- Place a 2 by 2 wooden piece on the work table or surface

- Next, placing the metal or steel part, you want to cut across the two wooden pieces

- Giving proper support by using a clamp-on on both sides. The clamp will keep both the metal piece and wooden piece fixed to the work table

- Next, the center of the circular hole is marked. The circle burner comes with a pointer that helps to make the mark

- Adjusting the circle shape cutter according to the size of the cut. The worker will consider the thickness of the material

- The torch is attached and turned on

- The flame moves in a circular motion along the center to ensure a precise circular cut

- After one or two minutes, the flame will make an arc as it cuts through the metal part.

- The worker will complete the rotation of the cutter to ensure that the arc is circular and then turn off the flame

- The metal piece cools down after one or two minutes, and then a hammer is used to force the cut piece out from the metal surface.

A circle cutter is a handy tool that can easily cut through steel alloys and stainless steel. It is easy to perform even difficult metal cutting tasks. The worker who uses the circle shape cutter must read the instruction manual and ensure proper safety.

Conclusion

The highest quality circular-cut requires a premium quality tool and a circle cutter serves the purpose effectively. The circle cutter is efficient, easy to use, and durable. This tool is best to get a clean and precise cut anytime and in any situation.